Hot keywords: Vacuum coating process PVD Coating Process Decorative film process

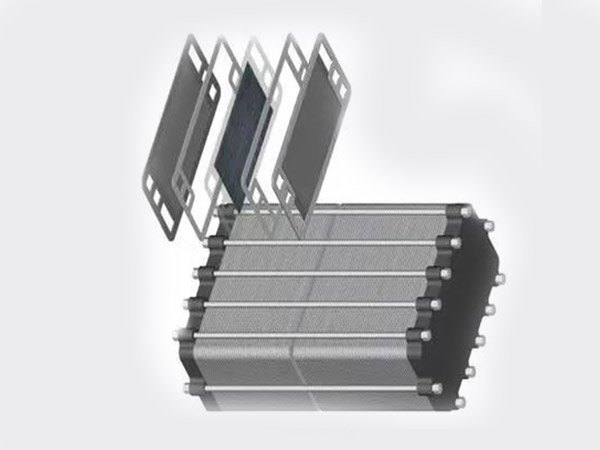

In 2017, Senfung invested around 10 million RMB for PVD equipment and materials to develop 20nm Au coating together with a hydrogen energy battery developer. Senfung has achieved Au coating which can meet contact resistance,corrosion current and aging test requirements after around 20 DOEs. The coating can pass 3000 hours endurance test.

In the April of 2020, Senfung has invested another 9 million to optimized the power supply of PVD equipment in order to achieve more stable gold coating with lower cost. In the September of 2020, Senfung set up another project team for bipolar plate to design and develop graphite coating. The graphite coating can pass contact resistance and corrosion current test witch has met international standards. In the March of 2021, additional investment for equipment and test devices to upgrade the graphite coating and optimized mass production. The R&D team has published two papers and registered a patent with this project.

Senfung was founded in 1998. We focus on PVD plating for metal parts. Our business covers watches,jewelry,mobile phone,smart wear,medical instrument,automobile parts and so on. We have strong technology and rich experience on decorative coating, functional coating and optical coating.

【Keywords】 pvd镀膜加工氢能源金属极板厂家 pvd镀膜加工

【Editor】

版权所有 © 2021-2039Shenzhen Senfung Vacuum Plating Co.,Ltd. All Rights Reserved.备案号:粤ICP备05103089号  粤公网安备 44031102000667号 百度统计网站地图

粤公网安备 44031102000667号 百度统计网站地图